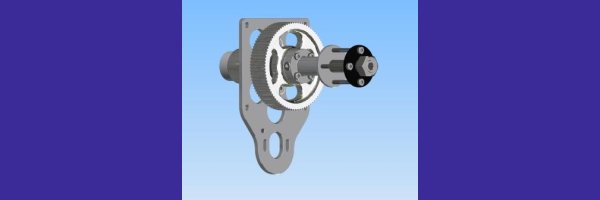

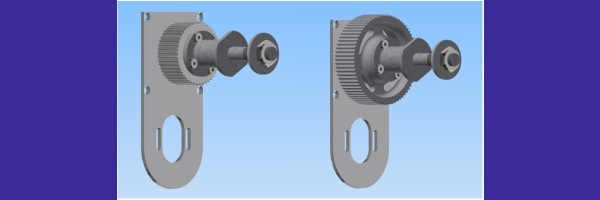

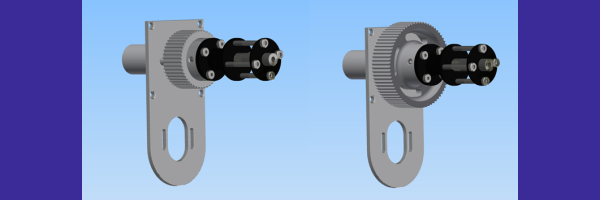

Timingbelt gears

The timingbelt gears of eAnSys are high performance gears with modern tooth profiles from GATES. The width is calculated to the performance needed and are usable for different duties in RC-modelling, everytime when the reduction of rpm in order to increase torque is needed.

This includes although outrunner engines which normally where used as direct drive.

Predestinated is the using in combination with outrunner Helicopter engines. There performance index is outstanding and often with gear better, then many direct drive engines. And the integrated air ventilation gives them another advantage in comparison. And with gear it is possible to adjust the engine very efficient to the need of the appropriate Airscrew. This allows an optimal performance in any case without buying a new engine.

A plus of variability and efficiency especially when using propellers with more then 2 blades.

In every case when it´s not possible to use the appropriate airscrew diameter in case of ground/ Chassis clearance, you have the opportunity to achieve the trust you need by using a more bladed airscrew. The rules therefore are simple:

coming from a 2-bladed airscrew, a 3-bladed airscrew with the same rpm, diameter, pitch and type needs the 1.6 factor of power and spend the 1.4 factor of trust. For a 4-bladed airscrew you will need the 2.2 factor of power and receive the 1.8 factor of trust. The efficiency decrease a little bit but it is still a often used way when you have to lower the airscrew diameter.

So the advantages of a timingbelt gear are in generally as follows:

- expansion option to use a direct drive engine up to 30% increased voltage ( using 12S instead of 8S)

- Increased engine efficency due to the higher voltage

- Therefore increased power output (using same current then before)

- increased torque corresponding to the used gear ratio

- adaption to the usage/ flight profile you are in mind (3D-flying, hover, etc)

- increased efficiency (up for 5% to15%) for the hole drivetrain

- very smooth running

- low-maintenance but not without maintenance!

The timing belt gears of eAnSys are engineered and calculated in CAD and where manufactured in Germany (Ostwestfalen-Lippe) on CNC machines. The mounting happens just in time after ordering.

Please get in contact with us if you need an individual Drive train (controller, engine, gear and airscrew) for your purposes. We will give you an proposal.

We like to offer you the right suggestion to your ideas or problems. Please ask!